We offer you commercial and residential hardwood floor, sanding, refinishing and staining.

When it comes to natural beauty it’s hard to beat the look and warmth of a real hardwood floor. Like most floor covering products, refinished hardwood flooring has changed dramatically over the past few years. Let us help you choose the right wood floor for your decor and lifestyle. We also offer expert wood flooring installation, and free estimates.

We match any color desired!

We install and finish new hardwood floors and repair and refinish existing hardwood floors. Hardwood flooring is durable, easy to maintain and comes in a wide variety of styles and colors.

When you are ready, give us a call to see and touch any of our fine wood floors.Sand and refinish hardwood floors

Refinishing of floor can be divided by two major sub categories: Mechanical and Chemical. At best we specialize in the mechanical refinishing of wood floors.Most wood floors can be successfully refinished by a process that, if done correctly, can increase the value and life span, provide protection, improve safety and finally give the floor a more pleasing appearance.

The most basic and natural floor has always been made of wood, which could be trace back to pioneer times across the United States in fact, some homes and churches that were build with wood floors moved west along with their owners. These wonderful floors could be removed and taken to the new location (try doing that with carpet). Most of these old floors were nailed down.

In the 60’s and 70’s, with the introduction of carpet and other synthetics such as vinyl, the production of wood floors plummeted this was accelerated by massive changes in building methods, where large tract of homes were build cheaply with slabs on grade. This concrete floor is not the best of sub floor for a solid wood floor. It was only after the development of proper glues that the flooring industry had come back to full production. Today to own a wood floor is not only prestigious it also provides a good, effective, long lasting and classy alternative to synthetic floors.We have extensive experience in refinishing all types of wood floors using only the latest equipment and employing only the most environmentally safe materials our goal is to provide the customer with the best floor available with the least amount of disruptions possible

New Floor Installation

There are as many different methods of installation as there are floor types.

First we need to find out what kind of floor you like. To answer this question you may consider the following:Existing substrate is the area the floor is going to be laid over is a raised foundation or slab. Is it above grade or below, close proximity to ocean, humid or wet areas, indoor or outdoors..?

Existing wood floors. Some applications are a given if there are existing floor to be matched, most solid floors are still in production by the big mills and if not. A solid floor can always be manufactured.

Use of floor. Is it commercial, residential, a dance studio, a stage or a night club?

Budget. There are different floor types and different grade for the same purpose to meet any check book.

Style. Colors and design may vary with the type of floor needed

After the proper floor has been chosen for the area, the method of installation will vary upon the use, budget and material limitations.

Installation of Solid Floors

Engineering wood glue down – Over Concrete

Concrete floors could be laminated with plywood and once plywood is applied the installation method become as over wood raised foundation. However, if budget, job site conditions and/or other factors are called for a direct glue down of solid over concrete it can also be done keeping all the next in tune:

Concrete must be dry for at list 60 days (due to the fact that as concrete cures it omits water and this water may be transferred to the solid wood floor)installation over partially cured or green concrete may be proven disastrous.

Concrete needs to be sealed. We recommend Deco-Rez or other epoxy resin type materials.

Short length stock and parquet floor are the contractor’s and industry’s recommendation as floors are almost never level or we always find highs and lows in concrete floors a short stock can handle this imperfections better then long stock the other reason for short stock is stress when wood is glued to concrete they are in a constant temperature and humidity variants this may effect the bonding and a longer board may delaminate in a higher rate then a short one.

Basements or below grade. A solid floor is not recommended to be glued directly over concrete.

In order to keep wood from the dangers of direct gluing to concrete, laminating the floor with plywood may be the way to proceed. There are three methods of plywood laminations:

A “floating floor.” A 1/8″ pad is laid over the concrete and two layers of 1/2″ plywood nailed to each other and are just resting upon the pad forms the deck upon the solid floors can be nailed down.

Sleepers or channels are laid under luan, mahogany, or under 5/8″ CDX plywood which then becomes the deck for the hardwood floor.

Glue and ramset nail plywood directly to the concrete.

Hardwood installation nail down

Over Wood, or Over an Installed Deck

Plywood must be dry (in the process of plywood manufacturing the peeled ply are left out in a yard where they are constantly kept watered to increase moisture content and elasticity). This moisture in plywood may increase time of acclamation and may harm finished floors which are kilned and dry. Plywood then must be purchased from a flooring supplier who keeps plywood both flat and dry. Some contractors cover the plywood floors with plastic and some prefer #15 felt and some do both at this time solid floor can be nailed. If the floor is wider then 3-1/4″ we recommend glue and nail.

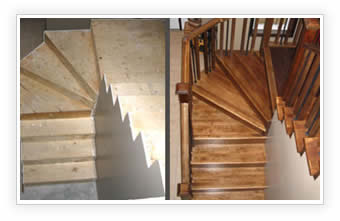

Wood stairs & handrails builders

Sand & refinish wood stairs